close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

What if the key to sustainable packaging lies in the adhesive that holds it all together?

As the world embraces eco-friendly solutions, laminating adhesives are becoming indispensable in crafting durable, sustainable packaging. Choosing the right laminating adhesive is essential for brands aiming to reduce their environmental footprint.

In this article, we’ll explore how laminating adhesives contribute to greener packaging, with a focus on products like YH-518A Paper Laminating Adhesive Paste.

Laminating adhesives are specialized bonding agents used to fuse multiple layers of materials together in packaging. These adhesives provide strength, durability, and protection to the final product, enhancing both functionality and appearance.

Laminating adhesives are typically water-based or solvent-based, designed to bond materials such as paper, plastic films, and cardboard. The adhesive is crucial in packaging where multiple layers are required to protect contents from moisture, UV rays, or physical damage.

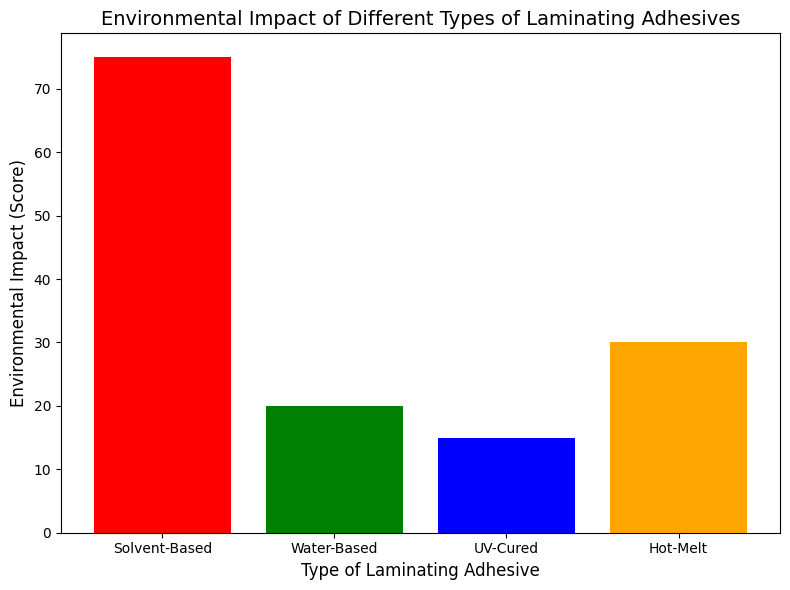

● Solvent-Based Adhesives: Offer high bonding strength but come with environmental concerns due to their VOC emissions.

● Water-Based Adhesives: A more eco-friendly option with lower VOCs, suitable for many packaging applications.

● UV-Cured Adhesives: Ideal for applications requiring fast curing times and strong bonds.

● Hot-Melt Adhesives: Known for quick setting times and ease of use, commonly applied in high-speed production lines.

Laminating adhesives play a pivotal role in reducing environmental impacts in packaging. Eco-friendly adhesive options help improve recyclability, reduce waste, and enhance the overall sustainability of the packaging materials.

Sustainable packaging reduces waste and minimizes the environmental footprint of packaging materials. By using eco-friendly adhesives, businesses can create packaging that is easier to recycle and more environmentally responsible.

Products like YH-518A, a water-based adhesive, help businesses move toward greener packaging solutions by reducing reliance on harmful solvents. This adhesive is used for high-quality paper boxes, including gift boxes, cosmetic packaging, and wine boxes, all of which are integral to luxury packaging solutions that align with sustainability goals.

When selecting a laminating adhesive, consider the following properties to ensure optimal performance for your packaging needs.

A strong adhesive bond is essential for packaging that will undergo handling, shipping, and environmental stresses. Products like YH-518A offer excellent initial adhesion, with the ability to bond in seconds and maintain strength over time, ensuring that the packaging remains intact.

Laminating adhesives need to be resilient to various environmental conditions. YH-518A, for instance, can withstand a wide temperature range, from -48ºC to 78ºC, ensuring that packaging remains intact regardless of external factors like heat, moisture, or UV exposure.

Eco-friendly adhesives, like YH-518A, are non-toxic and formulated to minimize environmental impact. These adhesives contribute to packaging solutions that are safe for consumers and the environment while maintaining strong bonding capabilities.

Each type of laminating adhesive comes with unique advantages and applications. Choosing the right adhesive is essential to meeting both functional and sustainability requirements.

While solvent-based adhesives offer superior bonding strength, they release harmful VOCs, making them less suitable for sustainable packaging. They are, however, still used in high-performance applications where strength is the primary requirement.

These adhesives are best for products requiring heavy-duty bonding, such as corrugated cardboard used in shipping and packaging for industrial products.

Water-based adhesives, such as YH-518A, are a greener alternative with low VOC emissions, making them suitable for sustainable packaging. These adhesives are non-toxic, environmentally friendly, and offer strong adhesion to materials like paper and cardboard.

Water-based adhesives are ideal for creating eco-friendly packaging, including high-quality gift boxes, cosmetic packaging, and wine boxes. They provide a strong bond while remaining compliant with eco-friendly packaging standards.

UV-cured adhesives are cured with ultraviolet light, providing a fast-setting solution that’s both efficient and durable. They are perfect for applications where quick turnaround times are necessary.

UV-cured adhesives are environmentally friendly because they do not release VOCs during curing, contributing to cleaner production processes. Their fast curing time reduces energy consumption, making them a sustainable choice.

Hot-melt adhesives are free from solvents and provide a quick, easy application process. They’re ideal for high-speed production lines and have a lower environmental impact compared to solvent-based adhesives.

These adhesives are often used in the production of corrugated boxes and other packaging materials that require fast assembly and durable bonds.

Choosing the right adhesive requires careful consideration of your material, production process, and environmental goals.

Consider the type of material being used for the packaging. Water-based adhesives like YH-518A work well with paper-based packaging, making them ideal for luxury packaging such as gift boxes, cosmetic boxes, and wine boxes.

Ensure that the adhesive complies with environmental regulations. Water-based adhesives offer a lower environmental impact compared to solvent-based options and are a better choice for sustainable packaging.

Different packaging materials require different adhesive properties. For example, luxury packaging like gift boxes and cosmetic boxes requires adhesives that provide a strong initial bond and long-lasting strength, all while maintaining flexibility.

For folding cartons and luxury gift boxes, adhesives like YH-518A provide strong bonding, perfect for delicate paper materials and ensuring high-quality finishes. They also work well for label applications, ensuring that the adhesive bonds effectively without harming the material.

When aiming for sustainable packaging, prioritize adhesives that are eco-friendly, like YH-518A. These adhesives contribute to a greener packaging solution that supports a company's environmental goals.

Look for adhesives with environmental certifications, such as ISO 14001 or FSC, which indicate that the adhesive is produced in an environmentally responsible manner.

Ensure that the adhesive complies with regulations like REACH and FDA guidelines, especially when used in food packaging or other regulated sectors.

Laminating adhesives, when used responsibly, can play a significant role in creating a more sustainable packaging system.

Products like YH-518A are derived from water-based formulations that reduce the reliance on petroleum-based chemicals. This shift toward bio-based ingredients helps reduce the carbon footprint of packaging materials.

Adhesives made from renewable sources help lower carbon emissions during production, contributing to a greener supply chain.

Eco-friendly adhesives ensure that laminated materials can be recycled more easily, reducing the overall waste produced by packaging.

Closed-loop systems, which involve the reuse and recycling of materials, benefit from adhesives that can bond and separate easily, such as those used in luxury gift boxes. Innovations in adhesive technologies make it easier to achieve zero-waste packaging systems.

Choosing the right laminating adhesive is essential for achieving both functional and environmental goals in packaging. Water-based adhesives, such as YH-518A, provide a strong, eco-friendly solution for packaging luxury items like gift boxes and cosmetics. By considering factors like adhesive properties, material compatibility, and sustainability, businesses can make informed decisions that contribute to a greener future.

At YOHO Chemical, we prioritize offering high-quality, sustainable solutions like YH-518A to help businesses meet their environmental goals.

● Select adhesives based on the material, environmental compliance, and packaging requirements.

● Eco-friendly adhesives like YH-518A offer sustainable, non-toxic bonding for various packaging applications.

● Always prioritize certifications and regulations to ensure your packaging is both high-performing and environmentally responsible.

A: Laminating adhesive is a bonding agent used to fuse multiple layers of packaging materials. It helps enhance the durability and protection of packaging while reducing environmental impact by enabling the use of recyclable materials.

A: To select the right laminating adhesive, consider the material type, environmental compliance, and packaging requirements. For eco-friendly solutions, water-based adhesives like YH-518A offer strong bonding with minimal environmental impact.

A: Laminating adhesives ensure packaging is strong, durable, and environmentally responsible. By using water-based or UV-cured adhesives, businesses can create sustainable, recyclable packaging solutions that align with eco-friendly practices.

A: Laminating adhesive is a broader category that includes various bonding agents for different packaging needs. Adhesive paste, like YH-518A, is a specific type of water-based adhesive paste ideal for bonding materials like paper for luxury packaging.

A: Yes, using eco-friendly laminating adhesives can make packaging easier to recycle and reduce waste by enabling the use of renewable and recyclable materials.