close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-22 Origin: Site

Have you ever wondered why some luxury packaging feels sturdier and more polished than others? The secret often lies in the choice of laminating adhesive.

In premium hardcover box production, selecting the right laminating adhesive is key to ensuring durability, aesthetic appeal, and long-term performance. This article will guide you through the factors to consider when choosing the best laminating adhesive, with a focus on high-performance options like YH-518A.

Laminating adhesive is a critical component in the production of hardcover boxes. It is the bonding agent that attaches the outer layers of materials—such as paper, fabric, or plastic—onto the structure of the box. In the case of premium packaging, the laminating adhesive not only holds the materials together but also helps in maintaining the box’s structural integrity under stress and wear.

YH-518A is an excellent example of a high-performance laminating adhesive. It is a one-component, water-based adhesive that excels in bonding packaging products like gift boxes, cosmetic packaging, and key boxes. What makes YH-518A so effective is its superior bonding strength, quick drying time, and environmental friendliness. These properties are especially important when manufacturing premium packaging, as they ensure that the adhesive will hold up over time, maintain the box’s appearance, and meet sustainability requirements.

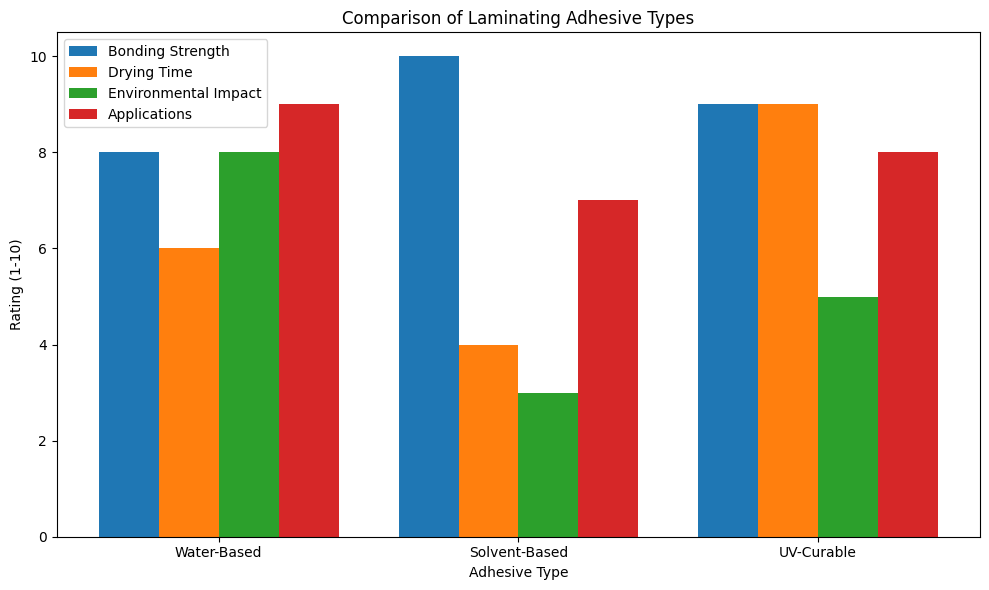

There are several types of laminating adhesives, each suited to different applications and materials. Understanding the differences between these adhesives will help you make an informed decision about which one is best for your specific needs.

1. Water-Based Adhesives: Water-based adhesives, like YH-518A, are popular in the packaging industry because they are eco-friendly, non-toxic, and offer strong bonding without emitting harmful fumes. These adhesives are also very versatile and can be used for both manual and automatic application processes. They are ideal for paper, cardboard, and other porous materials.

2. Solvent-Based Adhesives: These adhesives are known for their excellent bonding strength, especially when working with non-porous materials. They are widely used in packaging that requires heavy-duty bonding, such as for plastic or metal. However, solvent-based adhesives can emit strong odors and require additional precautions during handling due to their potentially harmful fumes.

3. UV-Curable Adhesives: UV-curable adhesives are cured quickly under UV light, making them perfect for high-speed production lines. These adhesives offer a high-strength bond and glossy finish, making them suitable for packaging that requires a premium look. However, the need for UV curing equipment can increase the cost and complexity of the production process.

The adhesive used in the production of hardcover boxes has a profound impact on both the durability and appearance of the final product. It is essential to understand how the adhesive influences key aspects such as strength, aesthetic quality, and long-term performance.

● Durability: The primary role of laminating adhesive is to hold the materials together, ensuring that the box does not separate or fall apart over time. A strong adhesive will ensure that the box can withstand handling, storage, and transportation without the risk of peeling or warping.

● Aesthetic Appeal: High-performance adhesives like YH-518A are designed to enhance the visual appeal of the packaging. They offer a smooth and even finish, preventing bubbling, wrinkling, or discoloration. The clear finish also allows for the true colors of printed designs and textures to show through, giving the box a polished, high-end look.

● Resistance to Wear and Tear: A good laminating adhesive also improves the box's resistance to physical stress. This includes resistance to abrasion, environmental exposure, and the stresses caused by regular handling, ensuring that the box maintains its structural integrity and appearance for a longer period.

When it comes to premium packaging, durability is a key concern. High-performance laminating adhesives like YH-518A provide a reliable bond that keeps the materials firmly attached, even under challenging conditions. The adhesive has strong initial adhesion, which means it begins sticking almost immediately upon application—within just 10 to 30 seconds. This rapid bonding helps ensure that the materials stay in place during the production process and beyond.Strong adhesion ensures that the box remains intact under physical stress. YH-518A provides excellent paper-breaking effects, ensuring that the adhesive does not peel off easily.

Hardcover boxes, especially those used for premium packaging, are often exposed to varying environmental conditions, such as temperature fluctuations, humidity, and sunlight. These environmental factors can cause many adhesives to lose their strength over time. However, YH-518A has exceptional resistance to both high and low temperatures, from -48ºC to 78ºC, making it suitable for a wide range of environmental conditions.

YH-518A is resilient against extreme temperatures, ensuring that the box maintains its strength in a variety of climates.

The adhesive provides stability and durability, even when exposed to moisture or humidity.

For premium packaging, the visual quality of the box is just as important as its functionality. YH-518A ensures that the packaging not only stays intact but also looks great. The adhesive offers excellent leveling properties, allowing it to spread evenly across the surface without causing bubbles or wrinkles. Additionally, it allows for a clear, glossy finish, making it ideal for luxury gift boxes, cosmetic packaging, and other high-end products.

YH-518A produces a smooth, high-quality finish that enhances the aesthetic appeal of luxury packaging.

○ Its ability to maintain clarity and prevent distortion ensures that printed designs are displayed vividly and attractively.

When selecting a laminating adhesive, the adhesion strength is one of the most critical factors to consider. The adhesive must form a strong bond with the materials used, ensuring that the box will not come apart during handling. YH-518A offers a high bond strength, making it suitable for a wide variety of substrates, including cardboard, paper, and textured surfaces. The bond strength is measured by its ability to resist peeling and delamination.

Always perform adhesion tests on sample materials before full-scale production to ensure compatibility and desired performance.

Another important factor to consider is the drying time and curing process of the adhesive. For high-volume production, it’s essential to choose an adhesive that dries quickly and allows for a fast production turnaround. YH-518A has a long open time of 15 to 30 minutes, giving you flexibility during the production process. The adhesive starts bonding quickly, which is ideal for automatic and manual application systems.

● Key Benefits:Long open time allows for flexibility during production.

○ Quick positioning and adhesion reduce production delays and improve overall efficiency.

For premium packaging that may be exposed to oils, solvents, or other chemicals, choosing a laminating adhesive with strong chemical resistance is essential. YH-518A excels in this area, providing long-lasting protection against chemical exposure and ensuring that the adhesive bond does not degrade over time.

Choose adhesives like YH-518A for packaging that is likely to encounter oils, solvents, or other chemicals.

Sustainability is an increasingly important factor in the packaging industry. Eco-friendly adhesives like YH-518A help reduce the environmental impact of packaging. These water-based adhesives emit low levels of volatile organic compounds (VOCs), making them a safer choice for both workers and the environment.

YH-518A is non-toxic and has a low environmental impact. Its water-based formula ensures that it is safe for use in a variety of applications, including luxury packaging.

One of the most common mistakes when selecting laminating adhesives is failing to consider the compatibility of the adhesive with the materials being used. Using an adhesive that is not suitable for the specific material can result in poor bonding and premature failure of the packaging. Always ensure that the adhesive is tested and compatible with the materials you are using, such as gold card paper, grey cardboard, or plastic.

Test adhesives on various materials before full-scale application. Ensure that the adhesive works well with the substrate to avoid issues during production.

Another common mistake is choosing an adhesive without considering the production timeline. Adhesives that dry too slowly or cure too quickly can cause delays in the production process. YH-518A offers an ideal balance between drying time and open time, ensuring that production is efficient while still delivering high-quality results.

Consider your production timeline when selecting adhesives to avoid production delays.

While cost is an important factor, it should not be the only consideration when selecting a laminating adhesive. Low-cost adhesives may seem attractive at first, but they could result in poor performance, which may ultimately lead to higher costs in the long run due to poor adhesion or a compromised product appearance. Always balance cost with performance to ensure that your packaging meets the required quality standards.

Don’t compromise on quality for the sake of cost. High-performance adhesives like YH-518A offer excellent value over time.

YH-518A is a prime example of a high-performance water-based adhesive. This adhesive is eco-friendly, non-toxic, and offers a strong bond for a variety of premium packaging materials. It is particularly effective for luxury gift boxes, cosmetic packaging, and key boxes, offering excellent durability and a clean finish.

Feature | YH-518A |

Adhesive Type | Water-Based |

Initial Adhesion | 10-30 Seconds |

Open Time | 15-30 Minutes |

Temperature Resistance | -48ºC to 78ºC |

VOC Level | Low |

Solvent-Based Adhesives are ideal for applications that require stronger bonding, especially when working with materials like plastic or metal. These adhesives provide excellent durability and are highly resistant to harsh environmental conditions. However, they tend to emit strong odors during application, requiring proper ventilation, and they have a higher environmental impact due to the chemicals involved.

UV-curable adhesives are ideal for fast-paced production environments. These adhesives cure quickly under UV light, allowing for rapid production cycles without sacrificing quality. They are perfect for creating high-strength bonds with a glossy finish.

● Pros:

○ Quick curing under UV light

○ High-strength bonds and premium finish

● Cons:

○ Requires specialized UV curing equipment

○ Can be more expensive than other options

Selecting the right laminating adhesive for premium hardcover box production is critical to ensuring both durability and aesthetic appeal. High-performance adhesives like YH-518A from YOHO offer numerous benefits, including strong bonding, environmental resistance, and an excellent finish. By considering factors like adhesion properties, drying time, chemical resistance, and environmental impact, you can ensure that your packaging meets the highest standards.

A: A laminating adhesive is a bonding material used to attach layers of material, such as paper or cardboard, to the structure of a box. It ensures that the packaging remains intact while providing a smooth, professional finish.

A: Selecting the right laminating adhesive ensures durability, aesthetic appeal, and environmental resistance. It helps the packaging maintain its appearance and strength over time, even when exposed to various environmental factors.

A: The laminating adhesive impacts the box's bonding strength, appearance, and resistance to wear and tear. A high-performance adhesive ensures the packaging holds together while maintaining a clean, glossy finish.

A: Key factors include adhesion strength, drying time, chemical resistance, and environmental impact. These will help you select an adhesive that ensures long-lasting, high-quality packaging.

A: Yes, water-based laminating adhesives like YH-518A are an excellent choice for luxury packaging. They offer strong bonding, low environmental impact, and work well with both manual and automatic applications.