close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-24 Origin: Site

In the world of large-scale paper processing, the right laminating adhesive can make all the difference. Whether it’s packaging or luxury gift boxes, the adhesive you choose impacts the final product's strength and visual appeal. YH-518A, a high-performance, water-based adhesive, is designed to meet these exact needs.

This article will dive into the key considerations for sourcing the best laminating adhesive and how optimizing this process can elevate production efficiency and product quality while reducing costs.

Laminating adhesives play an integral role in paper processing, particularly for bonding layers of paper together to create strong, durable packaging products. When it comes to premium packaging solutions such as gift boxes, cosmetic boxes, and handcover boxes, the adhesive used is essential for ensuring that the layers bond securely and remain intact throughout the product’s lifecycle. YH-518A adhesive, specifically designed for these types of applications, ensures a firm bond that prevents the separation of layers even after exposure to varying temperature and humidity conditions.

The strength of the adhesive ensures that the final product can endure physical stress during transport, handling, and storage without delaminating or losing its integrity. Moreover, adhesives like YH-518A help to enhance the aesthetic appearance of the final product, providing a smooth, even finish that is critical in luxury packaging applications where visual appeal is a top priority.

Selecting the right laminating adhesive is crucial for ensuring smooth and efficient large-scale production processes. When sourcing adhesives for applications such as handcover boxes and cosmetic packaging, it is essential to consider several key properties, including:

● Adhesive Strength: YH-518A offers strong initial adhesion, providing excellent positioning capabilities within 10 to 30 seconds. This quick setting feature is essential for high-speed production lines, where delays due to inadequate adhesion can disrupt operations.

● Drying Speed: The adhesive offers a long open time of 15 to 30 minutes, ensuring ample working time for operators before the adhesive sets. This allows for quick adjustments, improving workflow efficiency in both automatic and manual production environments.

● Environmental Resistance: One of the standout features of YH-518A is its ability to withstand extreme temperature fluctuations, with resistance to both high and low temperatures, ranging from -48ºC to 78ºC. This makes it an ideal choice for products exposed to various environmental conditions.

● Viscosity: With a viscosity range of 3000-5000 mPa·s, YH-518A has excellent leveling performance, making it suitable for both rotary pump adhesives and manual machine taping. This versatility ensures that the adhesive can be used across a variety of production lines without compromising quality.

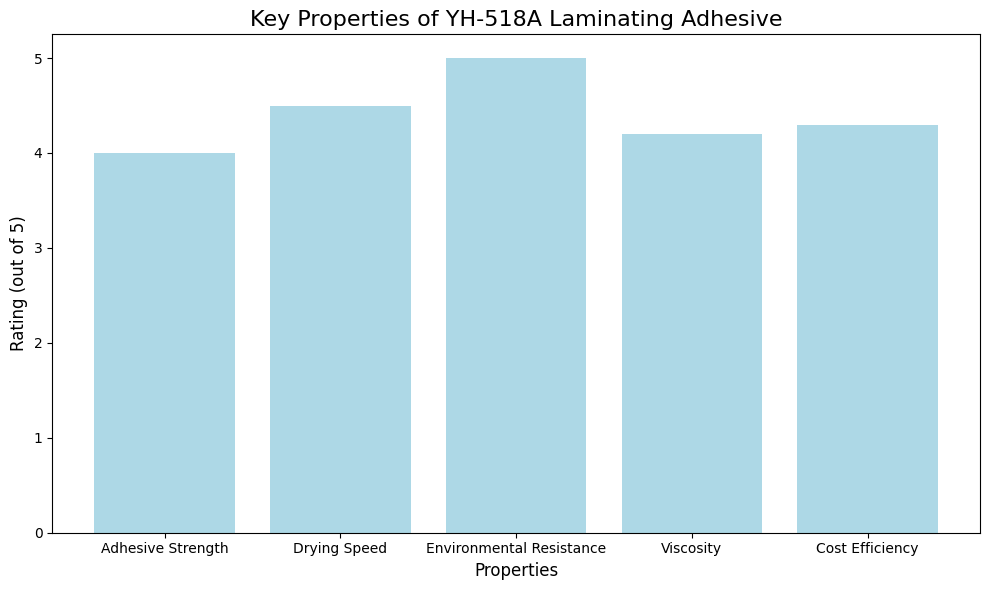

Here’s a quick visual overview of these key properties:

Sourcing high-quality laminating adhesives presents several challenges, particularly when ensuring consistency and reliability in the supply chain. YH-518A is a prime example of an adhesive that offers excellent performance, but sourcing such adhesives in large quantities and consistently can be difficult. Companies often face challenges such as fluctuating adhesive quality, supply chain disruptions, and difficulties in sourcing adhesives that meet both performance and budget requirements.

For manufacturers producing high-end packaging products like luxury gift boxes and cosmetic boxes, the adhesive’s performance is critical to the final product’s integrity. Any variability in adhesive quality can result in delays, defects, and substandard products, leading to increased costs and dissatisfied customers. Balancing the cost of the adhesive with its performance is therefore one of the most critical challenges in sourcing laminating adhesives.

One of the most important considerations when sourcing laminating adhesives such as YH-518A is evaluating the supplier's reputation. A reputable supplier ensures consistent product quality, timely delivery, and effective customer service, all of which are essential for maintaining smooth production operations. Sourcing adhesives from a supplier with a proven track record of reliability helps to reduce the risk of supply chain disruptions, ensuring that production schedules are not compromised.

Conduct thorough research on potential suppliers by checking reviews, certifications, and their history of meeting delivery timelines and quality standards. This will help ensure that your adhesive needs are consistently met without interruptions.

Laminating adhesives come in various formulations, including solvent-based, water-based, and hot melt adhesives. YH-518A is a water-based adhesive, which is considered a more environmentally friendly option. Water-based adhesives like YH-518A offer several advantages:

● Environmental Friendliness: Water-based adhesives are non-toxic and safer for workers, making them ideal for businesses that prioritize sustainability and worker safety. These adhesives have low volatile organic compound (VOC) emissions, reducing their environmental impact.

● Versatility: Water-based adhesives like YH-518A are suitable for various paper types, including grey cardboard, white cardboard, and copperplate paper, making them versatile for different packaging applications.

● Eco-Friendly Compliance: Many industries and regulations now require adhesives to meet specific environmental standards. Water-based adhesives meet these criteria, ensuring that companies remain compliant with sustainability regulations.

Understanding the benefits and drawbacks of each adhesive type is essential to choosing the best solution for your paper processing needs.

As sustainability becomes an increasingly important priority in many industries, sourcing environmentally friendly adhesives is crucial for maintaining compliance with both local and international regulations. YH-518A is a non-toxic, environmentally friendly water-based adhesive that offers excellent bonding performance while ensuring that manufacturers meet environmental standards.

Companies should prioritize sourcing adhesives that comply with environmental regulations, such as those related to low VOC content, recyclability, and overall sustainability. This not only helps companies avoid potential legal risks but also enhances their reputation as environmentally responsible businesses.

Accurate forecasting is essential to ensuring that your adhesive supply chain remains efficient and consistent. For large-scale paper processing, businesses must predict their adhesive requirements based on production schedules, seasonal demand, and market trends. Effective forecasting helps avoid both adhesive shortages, which can disrupt production, and excess inventory, which ties up valuable resources and increases storage costs.

One of the most effective ways to forecast adhesive needs is to track historical data and collaborate with suppliers to understand lead times and potential fluctuations in demand.

Leverage advanced inventory management systems to predict adhesive consumption based on production cycles and adjust procurement plans accordingly.

When sourcing laminating adhesives like YH-518A, companies often face the decision between local and international suppliers. Local suppliers provide advantages such as faster delivery times, lower shipping costs, and easier communication. In contrast, global suppliers may offer cost advantages due to economies of scale and larger production capacities.

For businesses that require a high volume of adhesives, international suppliers may be more cost-effective, while local suppliers are ideal for businesses that need smaller quantities with quicker turnaround times. Each option has its pros and cons, and companies must weigh factors such as production volume, shipping costs, and supplier reliability when making their decision.

Evaluate the trade-offs between local and global suppliers based on your production needs, considering factors like lead time, shipping costs, and overall supply chain efficiency.

Building long-term relationships with adhesive suppliers is one of the best ways to ensure a reliable supply of high-quality adhesives. Suppliers are more likely to prioritize customers with whom they have established trust and a solid working relationship. This can lead to better pricing, priority stock during high-demand periods, and quicker resolution of any supply chain issues that may arise.

Maintain open lines of communication with your suppliers, regularly discussing your production needs, forecasting requirements, and any potential challenges that could affect the supply chain.

While cost is an essential factor in sourcing laminating adhesives, it should not come at the expense of quality. YH-518A provides an excellent balance between performance and cost, making it a highly cost-effective solution for businesses that require high-quality adhesives without overspending. Finding the right adhesive involves evaluating the long-term benefits, including the reduction of production errors, the improved durability of the final product, and overall cost savings in the production process.

Perform a cost-benefit analysis to ensure that the adhesives you select offer a balance between quality and price, ultimately leading to greater operational efficiency.

Bulk purchasing of laminating adhesives can offer significant cost savings, especially for companies with high production volumes. However, bulk buying comes with certain risks, such as potential degradation of adhesive quality over time or excess inventory that might not be used before the adhesive expires.

Use inventory management systems to track adhesive usage and ensure that bulk purchases align with your production schedules to avoid wastage.

Quality control is crucial in ensuring that every batch of YH-518A adhesive meets the required performance standards. Rigorous testing, including viscosity tests and environmental resistance checks, ensures that the adhesive performs consistently across production runs. Ensuring consistent adhesive quality reduces the likelihood of defects, improving product quality and reducing waste.

Implement regular quality checks at each stage of the adhesive sourcing process, from initial supplier evaluations to final product testing.

Before committing to large-scale purchases of YH-518A, it is essential to test adhesive samples under real production conditions. This ensures that the adhesive performs as expected and meets your specific needs, such as adhesion strength, drying speed, and temperature resistance. Testing adhesive samples helps prevent costly mistakes and production delays down the line.

Conduct real-world tests of adhesive samples before finalizing procurement, ensuring that the product performs consistently in your specific production environment.

Regular supplier audits and performance monitoring are essential for maintaining high-quality adhesive sourcing. Audits help to identify any potential issues early, ensuring that suppliers maintain the necessary standards for product consistency and delivery.

Schedule periodic supplier audits and track performance metrics to ensure long-term reliability in your adhesive supply chain.

Sourcing reliable laminating adhesives like YH-518A is essential to optimizing large-scale paper processing. By considering factors like adhesive strength, environmental resistance, and supplier reliability, businesses can streamline their supply chains and enhance production efficiency. YH-518A is an ideal solution for manufacturers producing high-quality packaging products, offering excellent adhesion, environmental sustainability, and cost-effectiveness.

As you assess your adhesive sourcing strategies, consider adopting YH-518A to improve your supply chain and product quality while reducing costs. By following these strategies, you will be well-positioned to meet the growing demands of the packaging industry and maintain high-quality standards for your paper products.

With YOHO's commitment to delivering top-quality adhesives like YH-518A, you can rely on their expertise and dependable supply to elevate your production processes and ensure your packaging products meet the highest standards.

A: Laminating adhesive is a substance used to bond paper layers together, ensuring durability and strength in products like packaging and gift boxes. It is crucial for large-scale paper processing as it provides reliable bonding, ensuring that the final product withstands handling and environmental conditions.

A: When selecting a laminating adhesive, consider factors like adhesive strength, drying time, environmental resistance, and compatibility with different paper types. For high-quality packaging, adhesives like YH-518A offer a good balance of cost-effectiveness and performance.

A: YH-518A laminating adhesive paste offers quick adhesion, long open time, and strong resistance to temperature variations. Its environmental friendliness and non-toxicity make it ideal for high-end packaging products like gift boxes and cosmetic packaging.

A: Most laminating adhesives, including YH-518A, can be used on various types of paper, such as grey cardboard, white cardboard, and copperplate paper. However, it's important to choose the right adhesive paste that suits the paper type and production method for optimal results.