close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-25 Origin: Site

When it comes to packaging, the right laminating adhesive can make all the difference. Why is YH-518A favored by handcover box manufacturers? In this article, we’ll dive into its superior bonding power, eco-friendly qualities, and why it’s the go-to choice for premium packaging solutions. Discover how YH-518A stands out in the industry.

Laminating adhesives are integral to the packaging industry, particularly when it comes to the production of handcover boxes, gift boxes, cosmetic boxes, and other types of premium packaging. These adhesives are designed to bond different materials, such as paper, cardboard, and plastic, to enhance both the aesthetic and functional qualities of the packaging. A good laminating adhesive not only provides strong adhesion but also adds a layer of protection, helping to maintain the integrity and appearance of the packaging throughout its lifecycle. Whether it's for luxury items, cosmetics, or even wine bottles, packaging materials often need to withstand various environmental factors like moisture, heat, and rough handling, making the choice of adhesive crucial.

For manufacturers, using the right laminating adhesive ensures that their products are not only well-protected but also look visually appealing to consumers. Among the many options available, YH-518A has gained significant attention in the packaging industry due to its superior performance, environmental friendliness, and versatility.

YH-518A, produced by YOHO CHEMICAL, is a one-component, water-based adhesive that is specifically formulated for bonding packaging products, such as handcover boxes, gift boxes, cosmetic boxes, and key boxes. Known for its strong initial adhesion and excellent temperature resistance, YH-518A provides a durable and long-lasting bond that ensures the packaging remains intact, even under challenging conditions. The adhesive is designed to deliver high performance with easy application, making it a popular choice among packaging manufacturers.

The unique formulation of YH-518A allows it to create a smooth, even finish while ensuring a strong bond between paper, cardboard, and other materials. Manufacturers benefit from its ability to bond quickly, its versatility in various applications, and its non-toxic, eco-friendly properties. YH-518A also complies with international standards, making it safe for use in packaging products that will come into contact with food or cosmetic items. As such, it is a trusted option for manufacturers in industries that require high-quality, reliable packaging solutions.

Item | Indicator | Unit | Detection Method |

Appearance | White-colored liquid | - | QB/320217NDS01-2020 |

Viscosity | 3000-5000 | Mpa·S | QB/320217NDS01-2020 |

PH Value | 6±1 | - | QB/320217NDS01-2020 |

Solid Content (%) | 52±2% | wt% | QB/320217NDS01-2020 |

YH-518A stands out due to its exceptional performance across various types of packaging. Whether used for handcover boxes, gift boxes, or cosmetic boxes, this adhesive guarantees superior bonding strength. Its excellent leveling performance and consistent viscosity make it ideal for both manual and automatic application. YH-518A can be applied using rotary pump adhesives or manual taping machines, offering flexibility to manufacturers who may use different production methods. This versatility ensures that the adhesive can be adapted to various manufacturing environments without compromising quality or efficiency.

Additionally, YH-518A is designed to bond quickly. It achieves strong adhesion within just 10 to 30 seconds, allowing manufacturers to position and align materials efficiently. This quick setting time reduces production delays, increasing throughput and improving overall efficiency on the production line. The adhesive’s fast bonding capability also reduces the risk of misalignment, ensuring that the packaging materials are securely bonded the first time.

One of the primary reasons manufacturers choose YH-518A is its outstanding bonding strength. For handcover boxes and other premium packaging, having a reliable adhesive is essential to ensure that the box stays intact during handling and transportation. YH-518A provides a strong adhesive force that ensures a solid bond, making it ideal for applications that require durable and long-lasting packaging. The adhesive also features a strong paper-breaking effect, which is particularly useful when bonding paper or cardboard substrates. This characteristic ensures that the adhesive does not peel off easily or fail prematurely.

YH-518A's adhesion strength is especially critical when packaging high-end products, as a failure in the adhesive could result in damaged packaging and dissatisfied customers. The strength of the bond formed by YH-518A ensures that the packaging can withstand rough handling, weight, and transportation conditions, which is a crucial factor for manufacturers seeking to maintain high standards for product presentation and quality.

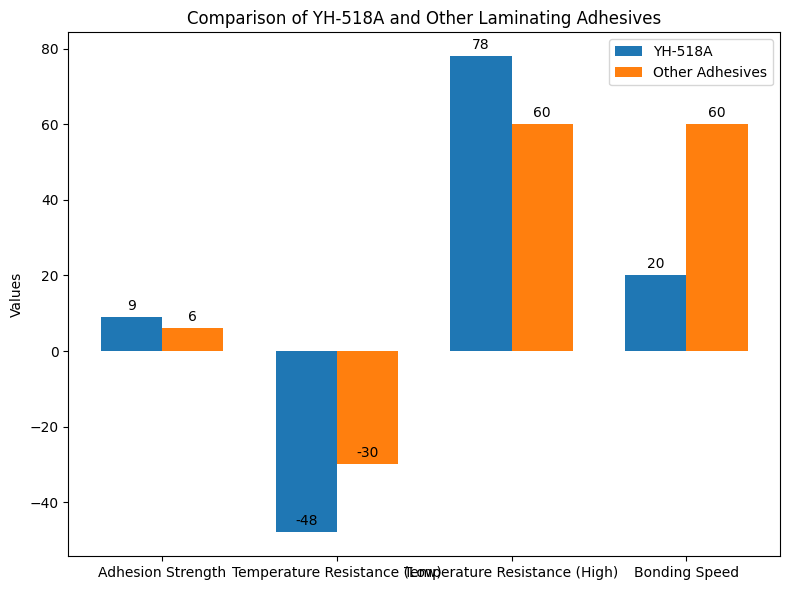

Durability is a crucial factor when it comes to selecting a laminating adhesive, and YH-518A excels in this area. The adhesive’s resistance to temperature extremes makes it suitable for packaging that will be exposed to various environmental conditions, such as shipping, storage, or retail environments. YH-518A is capable of maintaining its bond strength even in temperatures as low as -48ºC and as high as 78ºC, ensuring that the packaging remains intact and functional regardless of the surrounding conditions.

In addition to temperature resistance, YH-518A also offers long-term durability against moisture, dirt, and general wear and tear. This added protection ensures that the packaging maintains its visual appeal and structural integrity throughout its lifecycle, which is especially important for luxury or high-end packaging applications. Manufacturers can rely on YH-518A to deliver consistent results over time, reducing the need for rework or repackaging.

A laminating adhesive like YH-518A does more than just bond materials together; it plays a key role in enhancing the overall appearance of handcover boxes. With its smooth application and strong adhesion, YH-518A ensures that the surface of the box is even and free of defects. This glossy, professional finish is crucial for packaging products that need to stand out on the shelf or make a strong impression on consumers. For luxury packaging, where aesthetics are paramount, YH-518A offers a superior solution that enhances both the visual appeal and perceived value of the product.

The adhesive also helps preserve printed designs, logos, and graphics on the box. YH-518A creates a protective layer that ensures printed materials do not fade or smudge during handling, transportation, or storage. This helps maintain the integrity of the brand's visual identity and ensures that the packaging looks pristine when it reaches the end consumer.

In addition to enhancing appearance, YH-518A also improves the structural integrity of the packaging. Handcover boxes and other packaging materials often need to withstand rough handling, moisture, and exposure to the elements. YH-518A's adhesive properties add a layer of protection that helps resist damage from environmental factors. Whether the boxes are being stacked, transported, or stored for long periods, YH-518A ensures that the packaging remains stable and intact.

The strong adhesion provided by YH-518A also prevents boxes from losing their shape or collapsing. This is particularly important for packaging that holds delicate or fragile items, as a failure in the packaging could result in damage to the product inside. By using YH-518A, manufacturers can be confident that their products will reach consumers in the best possible condition.

Another significant advantage of YH-518A is its versatility. This adhesive is compatible with a wide range of materials commonly used in handcover box manufacturing, including gray cardboard, white cardboard, gold card paper, and copperplate paper. Whether the packaging is intended for luxury gift boxes, cosmetic boxes, or wine packaging, YH-518A ensures that the adhesive bonds securely to these materials, creating a consistent and durable bond across different types of substrates.

Manufacturers benefit from YH-518A's flexibility, as it allows them to experiment with different packaging designs and materials without worrying about adhesive compatibility. Whether using automatic, semi-automatic, or manual machines, YH-518A delivers high performance and reliable results in various production settings.

Paper Type | Applicable Machines | Application (Wet Adhesive) | g/m² |

Grey Cardboard | Manual, Automatic, Semi-automatic | 30-40 | 35-45 |

White Cardboard | Manual, Automatic, Semi-automatic | 30-40 | 35-45 |

Gold Card Paper | Manual, Automatic, Semi-automatic | 30-40 | 35-45 |

Copperplate Paper | Manual, Automatic, Semi-automatic | 25-30 | 30-35 |

Compared to other laminating adhesives, YH-518A provides superior bonding strength. This ensures that packaging materials stay securely in place throughout the product’s lifecycle. The stronger adhesion also minimizes the risk of packaging failures, reducing the likelihood of rework or customer complaints.

YH-518A requires minimal maintenance during production. Its strong initial adhesion and long open time make it easy to work with, even in fast-paced manufacturing environments. Unlike some other adhesives, YH-518A does not need frequent adjustments or reapplication, helping manufacturers save time and effort during the production process.

Despite its high performance, YH-518A is an affordable option for manufacturers. It offers a balance between quality and cost, making it an attractive choice for companies that need reliable adhesive solutions without exceeding their budgets. The adhesive’s durability further enhances its cost-effectiveness, as it reduces the need for frequent reapplication and rework, saving manufacturers money in the long run.

YH-518A complies with international safety and environmental regulations, ensuring that it is safe for use in various industries, including food, cosmetics, and luxury goods. The adhesive's non-toxic, water-based formula meets the strict standards required for packaging materials, giving manufacturers peace of mind knowing they are using a safe and environmentally friendly product.

As sustainability becomes a critical consideration for manufacturers, YH-518A offers an eco-friendly solution. It is formulated with low VOC content, which helps minimize the environmental impact. Manufacturers who use YH-518A can create packaging solutions that not only meet high-quality standards but also align with sustainability goals.

Many manufacturers have experienced significant improvements in their packaging processes after switching to YH-518A. For example, XYZ Packaging Ltd. reported a reduction in material waste and an increase in production speed, citing the adhesive’s ease of use and quick bonding time as major factors in their success. They also highlighted the excellent aesthetic quality of the boxes, which enhanced their brand image.

Manufacturers like ABC Packaging Co. have praised YH-518A for its superior adhesion and durability. Their team noted a marked improvement in the structural integrity of their handcover boxes, which allowed them to expand their product offerings. Additionally, the adhesive’s versatility in working with different materials allowed them to experiment with new designs without worrying about compatibility issues.

YH-518A, produced by YOHO CHEMICAL, is the top choice for professional handcover box manufacturers due to its excellent bonding strength, durability, and versatility. It delivers reliable performance, ensuring both aesthetic appeal and structural stability. With its eco-friendly formula and compliance with industry standards, YH-518A helps manufacturers create high-quality, cost-effective packaging solutions. When choosing a laminating adhesive, YH-518A stands out for its strength, durability, and ease of use, making it ideal for meeting the modern packaging industry's demands.

A: YH-518A provides superior bonding strength, quick adhesion, and durability, making it perfect for handcover boxes. Its excellent performance and temperature resistance ensure the packaging stays intact during handling.

A: YH-518A creates a smooth, glossy finish that enhances the visual appeal of handcover boxes. Its strong adhesion also preserves printed designs, ensuring they stay intact throughout the product’s lifecycle.

A: YH-518A is known for its superior bonding strength, quick application, and versatility. It’s eco-friendly, non-toxic, and provides long-lasting results, making it the preferred choice for premium packaging.

A: YH-518A can withstand temperature extremes from -48ºC to 78ºC, making it suitable for various environmental conditions. It ensures that the packaging remains intact, even in harsh environments.